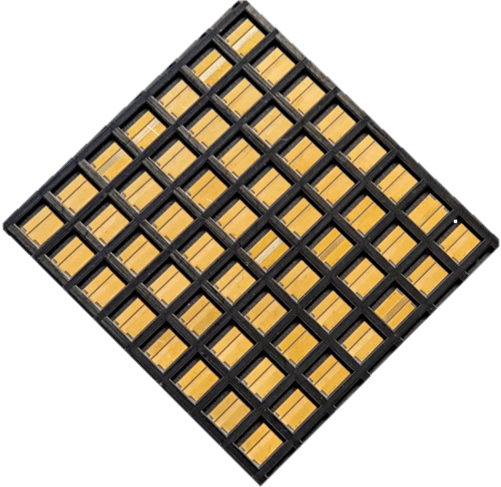

MetalEdge Emitting Laser

The Metal/Insulation-substrate/Metal three-layer structure design is a solution for handling heat dissipation issues in high-power laser chips, providing excellent thermal conductivity and insulation.

By controlling the thickness ratio of the metal layer and the substrate, the overall heat-dissipating substrate can be matched to the thermal expansion coefficient of the laser chip, ensuring high power performance and a longer lifespan for the laser chip.

Using thin film processes and photolithography techniques, the surface is metallized to create circuits.

Ceramic substrates inherently have high insulation, high thermal conductivity, and stable physical properties. When combined with thin film processes, the resulting circuits offer excellent adhesion, high surface flatness, and precise alignment, expanding the range of product applications.

features

- Metal bonding processes are carried out on substrates with high thermal conductivity and high insulation properties.

- The optimal ratio of metal layer to substrate thickness can be adjusted to meet the thermal expansion coefficient (CTE) requirements for various laser chips.

- There's no need for solder pullback at the critical edge in the laser chip die-bonding area, making it suitable for P-side-down laser chips.

- Custom designs for solder patterns can be provided.

- Sharp metal edges can be provided, suitable for high-precision alignment requirements when mounting laser chips (corner radius below 20μm).

- Substrate material options include Al2O3, AlN, SiC, and other high-thermal-conductivity substrates.

- Metal material options include Ti, Cu, Ni, Au, Pt, Pd, AuSn, among others.

Application

Industry

- Welding, cutting, label engraving, surface treatment.

- Unmanned factories and laser robots in the automotive industry

Medical or healthcare

- Ophthalmic lasers, cosmetic lasers, endoscopes.

Semiconductors

- Power semiconductor devices, annealing processes.